-

-

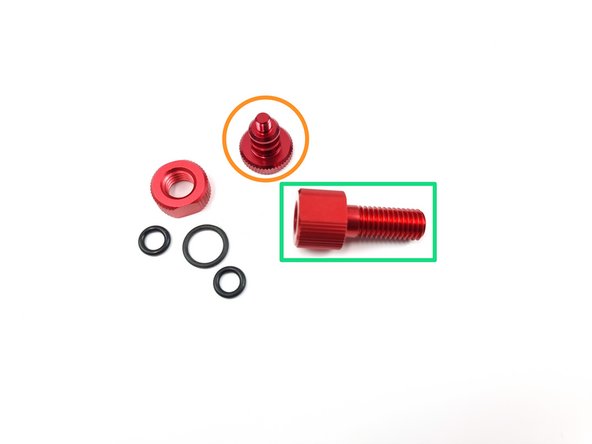

End Cap Flange

-

4 Hole End Cap

-

Face O-ring

-

Diameter O-Rings

-

M3 x 12mm Crews

-

-

-

Lubricate the O-ring with a thin layer of silicon grease.

-

Install the O-ring onto the penetrator

-

Insert the penetrator into one of the holes in the 4 hole end cap

-

Thread the nut onto the penetrator

-

-

-

Use the Penetrator Wrench to tighten the nut of the penetrator

-

To get a good tight fit use a spanner on the head of the penetrator while tightening with the penetrator wrench on the nut

-

-

-

Lubricate the O-rings with a thin layer of silicon grease.

-

Install the small O-rings on the plug

-

Install the large O-ring on the bolt

-

-

-

Insert and fit the bolt of the vent to the cap and tighten the nut on the back

-

Screw the plug into the vent

-

-

-

Lubricate the O-rings with a thin layer of silicon grease.

-

Install the O-ring onto the bolt

-

-

-

Insert the penetrator into the end cap.

-

Screw on the nut and tighten

-

-

-

Lubricate the O-rings with a thin layer of silicon grease.

-

Install the O-ring onto the bolt

-

-

-

Insert the penetrator into the end cap.

-

Screw on the nut and tighten

-

-

-

Lubricate with silicone grease and install the Face O-Ring into the flange.

-

Place the end cap onto the flange and install 4 of the M3 x 12mm screws as shown in the photo

-

Using a 2.5mm allen key tighten the screws down on the end cap

-

Follow this same procedure to install the 4 hole end cap on the second flange.

-

-

-

Lubricate the 2 O-Rings for the diameter of the flange.

-

Install the first o-ring onto the first groove.

-

Install the second o-ring into the second groove

-

Put the end cap aside until you are ready to install it into the acrylic tube

-

Keep the o-rings clean and free of dust. Put it into a zip-lock bag if possible

-

Almost done!

Finish Line